| Technical Parameter |

| Grab Overhead Crane for Garbage Main Technical Parameter | |||||||||||||||||||||||||||

| SWL (t) | 5 | 8 | 10 | 12.5 | 16 | 20 | |||||||||||||||||||||

| grab characteristics | volume (m3) | 2 | 4 | 5 | 8 | 10 | 12 | ||||||||||||||||||||

| self weight (t) | ~2 | ~3.4 | ~3.6 | ~5.3 | ~6.8 | ~7.6 | |||||||||||||||||||||

| working class | A8 | A8 | A8 | A8 | A8 | A8 | |||||||||||||||||||||

| span S(m) | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 | 22.5 | 25.5 | 28.5 | 31.5 | 22.5 | 25.5 | 28.5 | 31.5 | 25.5 | 28.5 | 31.5 | 34.5 | 28.5 | 31.5 | 34.5 | ||

| recommended speed | lifting speed | m/min | 0~30 | 0~40 | 0~45 | 0~50 | 0~50 | 0~45 | |||||||||||||||||||

| cross traveling speed | 0~30 | 0~44 | 0~50 | 0~50 | 0~46.5 | 0~50 | |||||||||||||||||||||

| long traveling speed | 0~50 | 0~50 | 0~65 | 0~70 | 0~67 | 0~63 | 0~65 | ||||||||||||||||||||

| power | lifting motor | Kw | 30 | 63 | 90 | 132 | 160 | 200 | |||||||||||||||||||

| cross traveling motor | 0.55*2 | 1.5*2 | 2.2*2 | 3*2 | 3*2 | 5.5*2 | |||||||||||||||||||||

| long traveling motor | 2.2*2 | 4*2 | 5.5*2 | 7.5*2 | 7.5*2 | 4*4 | 5.5*4 | ||||||||||||||||||||

| grab motor | 15 | 18.5 | 22 | 30 | 37 | 45 | |||||||||||||||||||||

| total power | 50.5 | 92.5 | 127.4 | 183 | 218 | 219 | 278 | ||||||||||||||||||||

| Max.wheel loading (kN) | 75 | 80 | 85 | 90 | 95 | 125 | 132 | 141 | 148 | 157 | 145 | 155 | 165 | 175 | 178 | 188 | 198 | 208 | 218 | 124 | 130 | 138 | 158 | 163 | 168 | ||

| traveling rail | I20 | I20 | I20 | I20 | I20 | I20 | |||||||||||||||||||||

| recommended long traveling rail | 43kg/m | 43kg/m | 43kg/m | QU80 | QU80 | QU80 | |||||||||||||||||||||

| power source | 3 AC 50Hz 380V | ||||||||||||||||||||||||||

| Overall Solutions |

| PLC Control System | |

|

|

| The PLC system adopts Siemens S7-1500/1200 and other world top class brands, which can operate continuously in high electronic noise, radio frequency interference and vibration environment, without reducing the performance of the system. |

| Electrical Driving System | |

.png) |

ABB ACS880DTC torque control frequency converter is adopted for the electrical transmission of lifting, cross travel and long travel mechanisms to drive the motor. The frequency converter has self-learning function for motor parameters and excellent speed regulation performance, can cooperate with the control system to ensure that garbage grab crane’s all mechanisms can start smoothly and stop accurately. |

| Electrical Driving System | |

|

ABB ACS880DTC torque control frequency converter is adopted for the electrical transmission of lifting, cross travel and long travel mechanisms to drive the motor. The frequency converter has self-learning function for motor parameters and excellent speed regulation performance, can cooperate with the control system to ensure that garbage grab crane’s all mechanisms can start smoothly and stop accurately. |

| Control Function List | |

| Control mode of the garbage grab overhead crane is divided into three working modes: manual, semi-automatic, and fully automatic. It can complete crane all actions, such as material moving, charging, and rearrange-stacking. The operation and control functions are shown in the table below: |

Control mode

Action process

|

Manual

|

Semi-automatic

|

Fully automatic

|

|

Material moving

Charging

Rearrange-stacking

|

material level

|

man observation

|

man observation

|

automatic

|

select grab point

|

man observation

|

man observation

|

automatic

|

|

select charging point

|

man observation

|

man observation

|

automatic

|

|

crane starting

|

man operation

|

automatic

|

automatic

|

|

move to grab point

|

man operation

|

automatic

|

automatic

|

|

grab fall down

|

man operation

|

automatic

|

automatic

|

|

garbage grab

|

man operation

|

man operation

|

automatic

|

|

grab and lift synchronously

|

automatic

|

automatic

|

automatic

|

|

lift grab

|

man operation

|

automatic

|

automatic

|

|

move to charging point

|

man operation

|

automatic

|

automatic

|

|

weighing,metering,count

|

automatic

|

automatic

|

automatic

|

|

open grab-unloading

|

man operation

|

automatic

|

automatic

|

|

back to grabing point

|

man operation

|

automatic

|

automatic

|

|

repeat above process

|

man operation

|

automatic

|

automatic

|

|

move to crane parking position

|

man operation

|

automatic

|

automatic

|

|

automatic fault diagnosis and alarm

|

automatic

|

automatic

|

automatic

|

|

remote online fault diagnosis

|

yes

|

yes

|

yes

|

|

| In any control mode, there is a manual control function, and manual control has the highest priority. At any time, as long as the operator touches the operating handle of the linkage platform, the automatic control mode will immediately stop and switch to manual mode. |

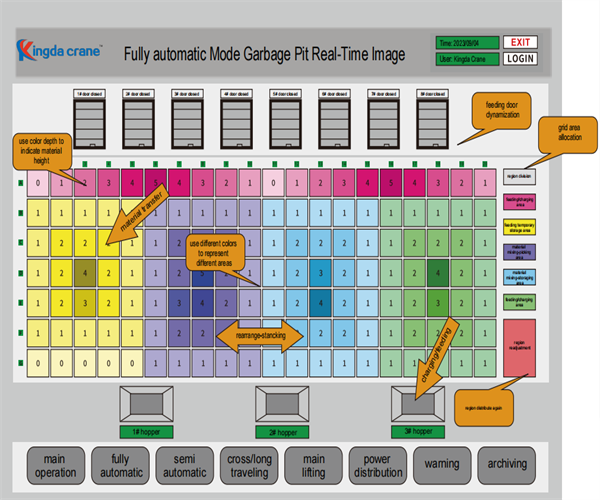

| FULLY AUTOMATIC MODE | |

| In fully automatic mode, fully automatic garbage grab overhead crane has four processing steps : | |

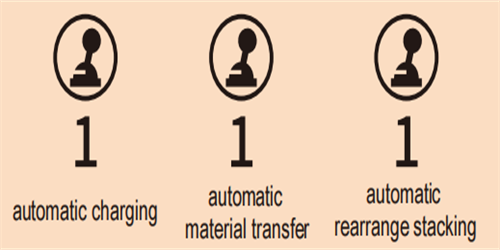

| Priority level:automatic charging>feeding scanning>automatic material transfer>automatic rearrange-staking | |

|

If the three buttons of "automatic charging", "automatic material tr- ansfer", and "automatic rearrange-stacking" are all set to "1", then automatic charging takes priority, followed by feeding scannin, au- tomatic material transfer again, and finally automatic rearrange st- acking. As long as the "automatic charging" signal is set to "1", the material grabbing and picking area is the charging area. |

|

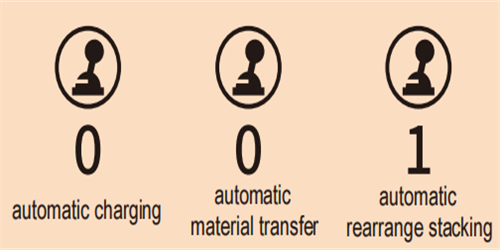

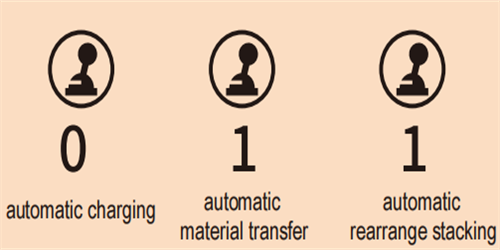

If the "automatic charging" signal is "0" and the "automatic material transfer" and "automatic rearrange-stacking" are set to "1", then the grabbing area is feeding area. |

|

If "automatic charging " and " automatic material transfer" are set to "0", and "automatic rearrange-stacking" is set to "1", the picking area is rearrange-stacking area. |

| material dumping area priority level: material incoming temporary storage area>rearrange-stacking temporary storage | |

| As long as the signal for automatic material transfer is "1", material dumping area is storage area; Only "automatic rearrange-stacking" signal is set to "1", the material dumping area is the rearrange-stacking discharge area. |

| Fully Automatic Charging Process |

| Set the "Automatic charging" button to "1", and set the "Automatic Material Transfer" and "Automatic earrange-stacking" Feeding Port Scanning buttons to "0", the garbage crane can automatically complete the charging process. |

move to material picking area automatically

|

grab material in highest point automatically

|

traveling and chargingautomatically

|

| If any hopper sends a feeding request, the garbage crane will automatically retrieve materials from thefeeding area and feed them tothe corresponding hopper. | ||

| If multiple hoppers issue a feeding request signal, the garbage crane will feed eachhopper one by one. | ||

| If there is no hopper feeding request signal and there is a material height scanning signal for the feeding door (when the feeding door isopened and closed, a scanning signal is issued), garbage crane will run to the corresponding feeding door to scan the garbage height. After completing the scanning, it will be in a waiting state. | ||

| If there is no feeding request from the hopper and no feeding scanning signal, the garbage crane will be in a waiting state. | ||

| Fully Automatic Rearrange-Stacking | ||

| Set "automatic rearrange-stacking" button to "1", "automatic charging/feeding", and "automatic material transfer" to "0". | ||

.png)

move to rearrange-stacking area automatically

|

grab materialautomatically and send to rearrange-stacking mixing area

|

dump material in low areas automatically

|

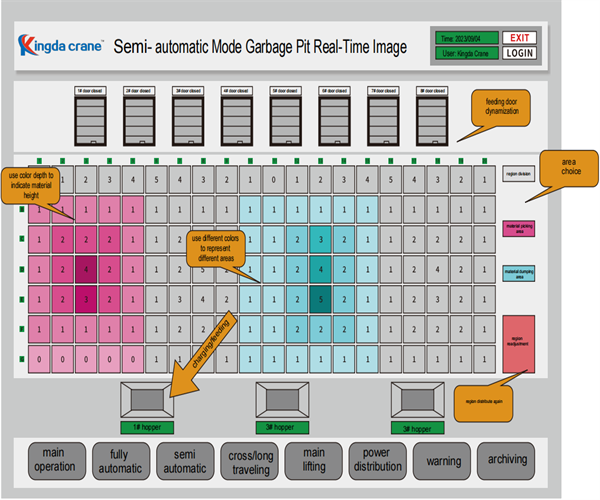

| Semi-Automatic Material Transfer Process | ||

| Set "automatic material transfer" to "1", "automatic feeding" and "automatic rearrange-stacking" to "0", the garbage crane is in the automatic material transfer process. | ||

Automatic scanning of material level height

|

Automatically grab materials and send to temporary storage area

|

Automatic scanning of material level height

|

| If feeding door does not send out feeding scanning signal and materialheight infeeding area is greater than the set value, garbage crane will automatically grab material from the highest point or grid by grid in feeding area, and automaticallyplace it in the lowest grid or grid by grid intemporary storage area; | ||

| If there is a feeding scanning signal, the garbage crane will complete this operation and automatically scan garbage height at corresponding feeding door. | ||

| If material height of the in feeding area is lower than the set value, the material transfer action stops. |

||

| Feeding Port Scanning |

| Automatic detection of feeding door opening and closing |

Automatic travelling to the feeding area | material height automatic scanning |

| If there is no automatic feeding signal and a feeding request signal, garbage crane will automatically run to the corresponding feeding port to scan the material height. |

| Fully Automatic Charging Process |

| Fully Automatic Monitoring of Material Status inn Garbage Poll | Semi-Automatic Monitoring of Material Status in Garbage Poll | |||||||

| semi-automatic operating mode | ||||||||

| semi-aotomatic starting | semi-aotomatic manual grabing and traveling | semi-aotomatic dumping traveling | semi-aotomaticfeeding /charging traveling | Automatic parking | ||||

| set the "semi-automatic button" to "1 "and all other working mode buttons to "0". At this time, the garbage crane is in a waiting state for semi auto-matic operation. | manually select the grabbing position of garbage crane on the touch screen,and the garbage crane will automatically go to the feeding area to grab the material. After grabbing the material,lift it to a certain height and wait for the next operation command. | Manually select the feeding position on the touch screen, and the garbage crane will automatically run to the dumping area for spraying. After dumping, the grab will be raised to a certain height and in a waiting state. | Garbage crane is in a waiting state after grabbing the material,by pressing loading button on touch screen, garbage crane will automatically run above the designated loading hopper to load.After loading is completed, garbage crane will automatically move to the garbage pit and wait for the next action. | After completing other actions, the garbage crane is in a waiting state. Set the "Park" button to "1" and then "0", and the garbage crane will auto matically run to the designated parking position. | ||||

| Manual Working Image | |

.png) |

In manual mode, the operation of the garbage crane is completed by garbage crane operator. Set "semi-automatic button" and "fully automatic button" to zero, and at this time, the garbage crane is in manual mode. |

| The long traveling mechanism, cross traveling mechanism, lifting mechanism, and grab opening / closing of the garbage crane are all controlled by handles or buttons on the linkage platform. For example, to drive the bridge to the left at fourth gear speed, simply manipulate long traveling handle to left at fourth gear, and the bridge will run at fourth gear speed. | |

| The control of lifting and trolley mechanisms in manual mode is the same as long traveling mechanism. The opening and closing of the grab is controlled by the aircraft head button on the lifting handle. Clicking "Open" will open the grab, and clicking "Close" will close the grab, meeting the requirements of manual material grabbing, charging/feeding, and discharging | |

| Manual Working Image |

| Calibration instructions | Warning | |

| ● lifting origin point calibration: open operating setup switch-press lifting calibration switch-close setup switch ● crossandlong traveling origin point calibration:open operating setup switch-press cross and long traveling origin position calibration switch - close setup switch ● landing calibration:open operating setup switch-press landing calibration switch - close setup switch ● empty grab calibration:open operating setup switch-press emprty grab calibration switch - close setup switch ● full grab calibration:open operating setup switch-press full grab calibration switch - close setup switch ● crane parking calibration:open operating setup switch-crane parking calibration switch - close setup switch ● 1# hopperpositioncalibration:open operating setup switch-1# hopper position calibration switch - close setup switch ● 2# hopperpositioncalibration:open operating setup switch- 2# hopper position calibration switch - close setup switch ● 3# hopperpositioncalibration:open operating setup switch- 3# hopper position calibration switch - close setup switch ● each decelerationpositioncalibration:open operating setup switch - each deceleration corresponding position calibration switch - close setup switch |

● Calibration operations can only be carried out after the crane is started, and calibration process must be strictly followed during calibration; ● After the calibration of cross and long traveling origin position crane parking and each hopper positions, semi-automatic operation verification should be carried out. Carefully observe the operation path in advance to see if it is abnormal. ● If it is abnormal,immediately snap the emergency stop button and re-calibrate.The lifting deceleration bypass and trolley deceleration bypass should be used in a timely manner under special circumstances and are not allowed to be used during normal operations.When the signal light is white, there is a deceleration limit, and when the signal light is green, there is no deceleration limit. |

| comprehensive protection |

lifting mechanism |

trolley mechanism |

bridge mechanism |

communication diagnosis and settings |

fault alarming | exit |

| Anti-swayTechnology | Precise Positioning Technology | |

|

|

|

| Adopting patented technology invented by Kingda crane, comprehensively utilizing the physical principle of load swing and the model is established by measured crane experimental data,to calculate and predict amplitude and loadswing phase.Based on this simulated manual operation environment, PLC high-level language programming control box on-site communication technology is used to control garbage crane's long and cross traveling speed inreal-time, significantlyreducing crane's swing range and greatly improving garbage's production effi-ciency. | By adopting patented technology invented by kingda crane,real-time monitoring and feedback of the garbage crane'soperatingpositions of cross /long traveling and grab, to obtain accurate three-dimensional positions of the grab space.Coupled with frequency converter cont-rol box's anti-sway function,fixed point adjustments are added toeach mechanism to ensure positioning accuracy and greatly improve working efficiency of the garbage crane. |

| Intelligent Estimate Technology | |

|

Adopting Kingda crane's invention patent, in order to ensure that the garbage crane can automatically determine appropriate garbage grabbing position, the garbage storage pit is virtual divided into a grid of unit units.During garbage crane’s operation,the entire garbage storage pit is scanned in real time,and the height of materials in each grid of garbage pit is recorded. Then, the height of garbage in corresponding grid is represented by a change in color. Garbage crane automatically selects and compares, and calculates the optimal grip-ping point. |

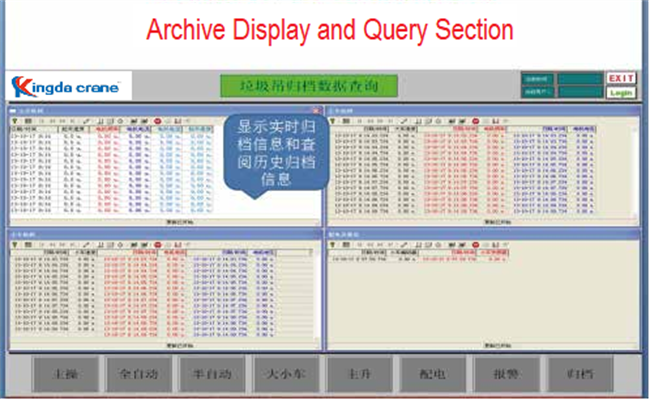

| Data Archiving and Monitoring Technology | |

|

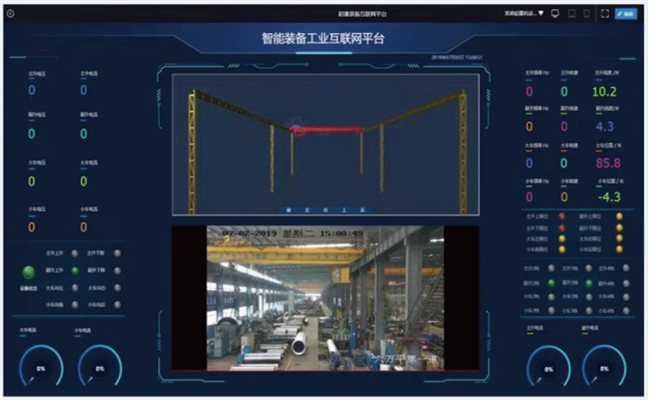

Using configuration software,establish a real-time monitoring animation that can reflect the three-dimensional position and grab status of the garbage crane in real time, and monitor status of garbage crane's key components in real time and dyn amically. Archive historical data, archive queries, and print reports on the main parameters and alarm information of the garbage crane. |

| Remote Service Technology | |

|

In order to ensure the reliable operation of garbage crane, crane’s standard confi guration is a remote service system with remote monitoring and diagnosis functio ns through a wide area network. Remote monitoring and diagnostic functions can provide customers with historical data query, rapid repair services for product fail ures, preventive maintenance of equipment, and basic data support for equipmen t failures and safety accidents for regulatory authorities. |

| monitoring system includes monitoring screen |

| There is weighing device (equipped with 4 weighing sensors) installed on the crane trolley for weighing measurement and overload protection. The weighing sensor is installed between the upper and lower trolley frame, allowing lifted object’s weight to fully act on the sensor,improving weighing accuracy.The static weighing accuracy is better than ± 1%, and it also has an overload alarm function. | |

| When the crane is located above the feeding hopper, the garbage caught by grab is automatically weighed. Each reading includes: garbage net weight, feeding position, and time.Each feeding hopper is equipped with its own counter and the weight reading is transmitted to the DCS system. This allows the crane to automatically record and organize the operating conditions and f eeding amount, automatically archiving them into Excel or Word reports, which can be printed and copied; The report includes each incinerator and the total amount of waste entering the furnace, including shift, day, week, and month reports. |

| monitoring system includes monitoring screen |

| Sensors are installed to detect the height of garbage in garbage bin and the position of garbage crane’s lifting, cross traveling and long traveling, respectively detecting the lifting height of garbage and the position of the lifting mechanism, as well as cross traveling and long traveling mechanisms. | |

| Garbage height is detected using a laser scanning system, and the position of garbage crane’s lifting mechanism,cross traveling mechanism and long traveling mechanism are detected using an encoder. | |

| According to the coordinate positions provided by encoders of each crane mechanism, the frequency converters of each crane mechanism drive the motors to this position | |

| Equipped with a position correction device, it avoids position errors caused by wheel slip. | |

| There is a "soft limit" designed in the program for functions such as proximity protection and parking protection. | |

|

|

| Laser scanning device | Absolute encoder |

| The laser scanning system is installed in workshop or on the crane to scan the height of the garbage in garbage pool in real time.The height value is transmitted to the PLC for processing,which grabs highest point in garbage pool and places it in hopper for incineration.It is also used for mixing and material transfer processes. | According to the actual situation of the garbage pool, a"step-by-step" method can also be used to grab materials,completing the process of loading, mixing, and moving materials. |

| Multi-Jaws Hydraulic Grab | |

| Grab adopts multi-jaws hydraulic grab, low center of gravity. | |

| Four point 'V' shape | |

| The connecting steel wire rope between crane and grab is arranged in a four point "V" shape to reduce twisting during use of the grab and collisions between grab and building. A transitional chain is used to connect grab and steel wire rope. | |

| reventing tipping | |

| The grab is equipped with sensor device that can detect tilt of the grab and prevent it from tipping over. | |

| Dynamical system | |

| he power supply voltage of multi-jaws hydraulic grab is 380-600V, and the open-close of grab is completed by a hydraulic oil pump driven by an electric motor. Control system is transported to the control room through cables on the cable drum. | |

| Independent control buttons | |

| The grab has a set of independent control buttons for personnel controlling operation. | |

| Protective measures should be taken between two grab cranes to prevent collisions. In order to maintain an appropriatedistance between two cranes, anti-collision devices are used. If the distance between cranes is closer than a specified distance, the power supply driving the motor of the mechanism will be automatically cut off. Two switch off points are programmed: first, cut off full speed but allow travel at low speed, and then stop according to the end switch point.The position detection error of traveling direction can be adjusted in crane control system |

| Both the long traveling and cross traveling are powered by cables, which use flexible circular towing cables (flat towing cables) for power supply |

| For secure and proper installation, all cables between the low-voltage switch and crane operating room, as well as between low-voltage switch and main power supply box, fixed type cables (CEFR cables) are used, and installed in cable ducts or conduit |

| -Discharging door | |

| Opening and closing status of the discharging door, as well as crane's fault signal, will be sent to the crane PLC; | |

| Crane in working state, PLC transmits crane’s working status signal and the signal of entering in to discharging door area (switch value) to the discharging door control system,to open or close discharging door conveniently, and protect grab. |

|

| -Crane PLC and DCS communication | |

| Crane PLC to DCS DCS cumulative value of crane grab feeding needs to be transmitted to DCS | |

| Single from DCS to PLC level signal of each feeding hopper is connected to the crane PLC DCS transmits the working status signal of each incineration line to crane PLC. |

|

|

|

|

|

Kawata Enviroment Equipment Group Co. Ltd

|

|

Environmental Protection Engineering

|

|

|

|

|

Biomass Power Project

|

|

Environmental Protection Engineering

|

|

|

|

|

Domestic Waste Incineration Cogeneration Project

|

|

Biomass Energy Project

|

|

|

|

|

Environmental Energy Project

|

|

Waste Incineration Power Generation Project

|