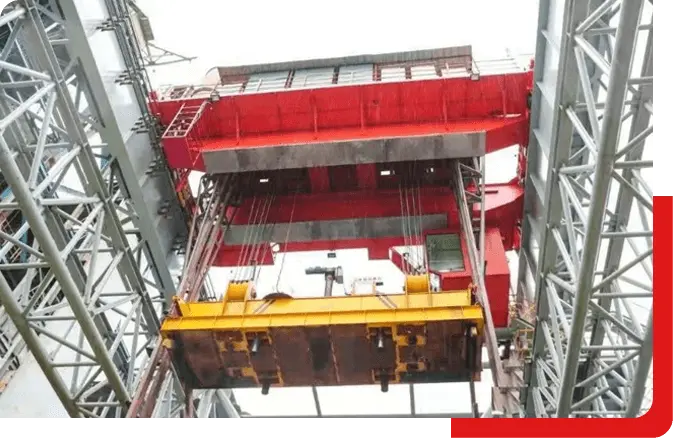

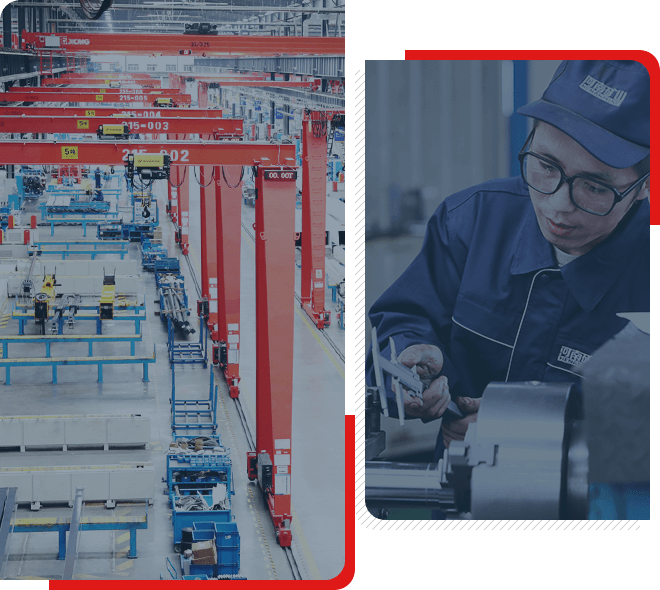

Fully automated cranes demand high availability

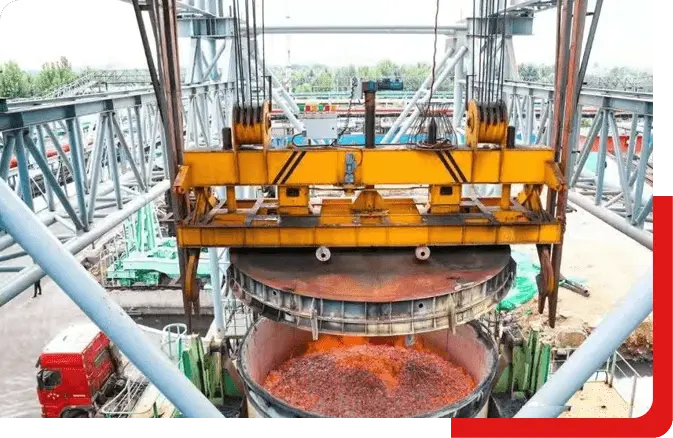

The coke pit is the production heart of a petrochemical plant, a harsh environment full of moisture, corrosive fumes and abrasive dust. Work is fast and continuous, and downtime is crippling to production. Konecranes can provide lifting equipment and service that can meet these challenges safely and efficiently.

For explosion-proof crane, there are dust explosion and gas explosion, the end user should analyze the hazardous factor, hazardous temperature and explosive area, then apply suitable crane in easy combustion and explosion